Introductions of PCHE, FPHE, HX²s

- Share

- Issue Time

- Apr 1,2020

Introductions of PCHE, FPHE, HX²s

PCHE (Printed Circuit Heat Exchangers), a new type of heat exchanger with high compactness, can perform heat transfer under severe conditions such as high temperature and high pressure. Using chemical etching technology, it can etch PCHE heat exchange unit channels on the order of micrometers to millimeters.

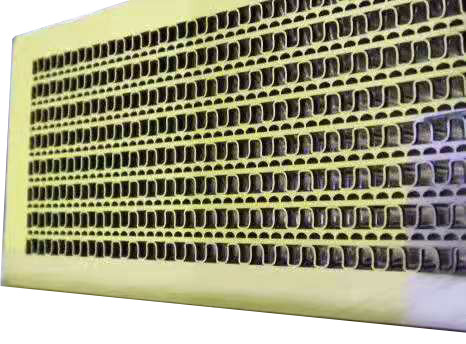

FPHE (Diffusion bonded plate fin heat exchangers), are suitable for gas-liquid and gas-gas heat transfer. Compared with brazed plate-fin heat exchangers, they are solder-free and have strong corrosion resistance (chlorine, acid, alkali, ammonia, Mercury, etc.), high and low temperature resistance (-200 ~ 900 ° C), high pressure resistance (4-15MPa), low leakage rate (1 * 10-9Pa · m3 / s), wide range of materials (titanium, stainless steel, nickel copper, etc ). At the same time, the secondary bonding does not have any effect on the core of the diffusion welding.

HX²s (Diffusion bonded hybrid heat exchangers), to a micro channel, stagger my article and plate fins, and use precision diffusion bonding technology to become one. Hybrid heat exchangers combine the advantages of micro-channel and plate-fin heat exchangers. Micro-channel plates on the cold side have high temperature and pressure resistance, and plate-fin mechanisms on the hot side have the advantages of large flux and low pressure drop...