Summary

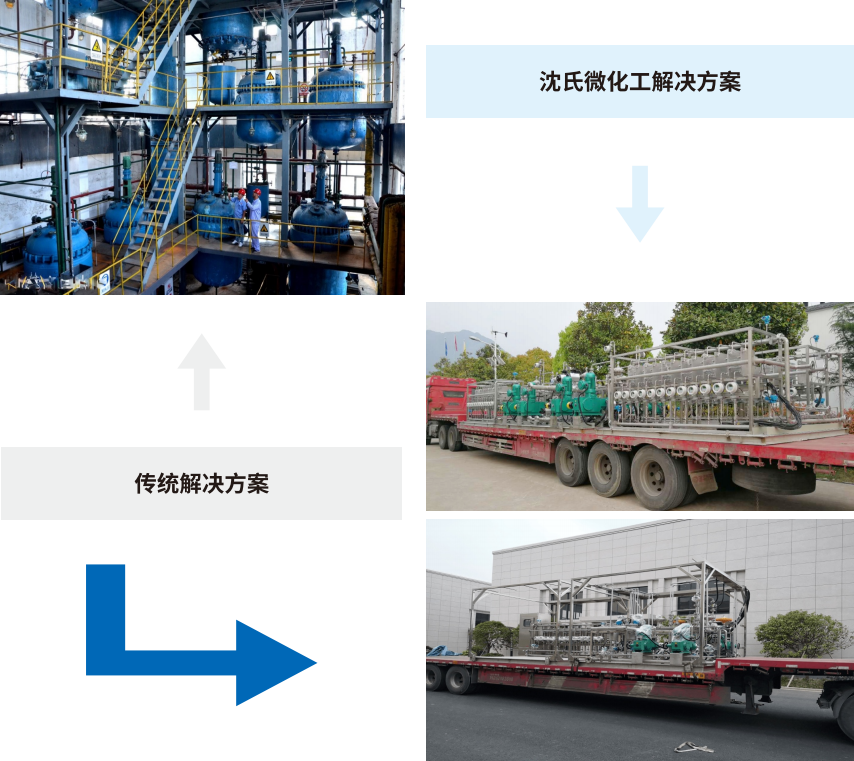

Yangnong Chemical's original pesticide intermediate production unit with an annual output of 7,000 tons occupies a large area, consumes a lot of energy, and has certain safety hazards. Compared with the original unit, the new system occupies only 23 square meters, which is nearly 90% less, and the continuous reaction time is shortened to one thousandth of the original. The amount of wastewater generated is also greatly reduced to 4.3% of the original.