Summary

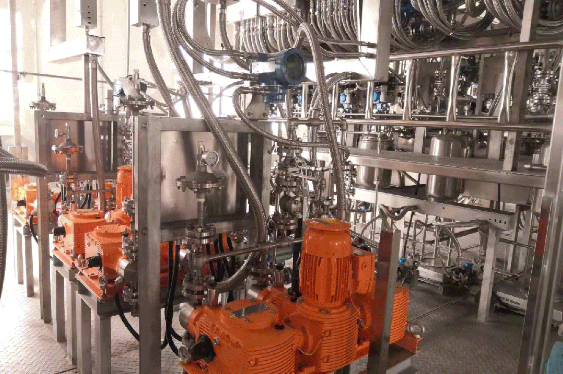

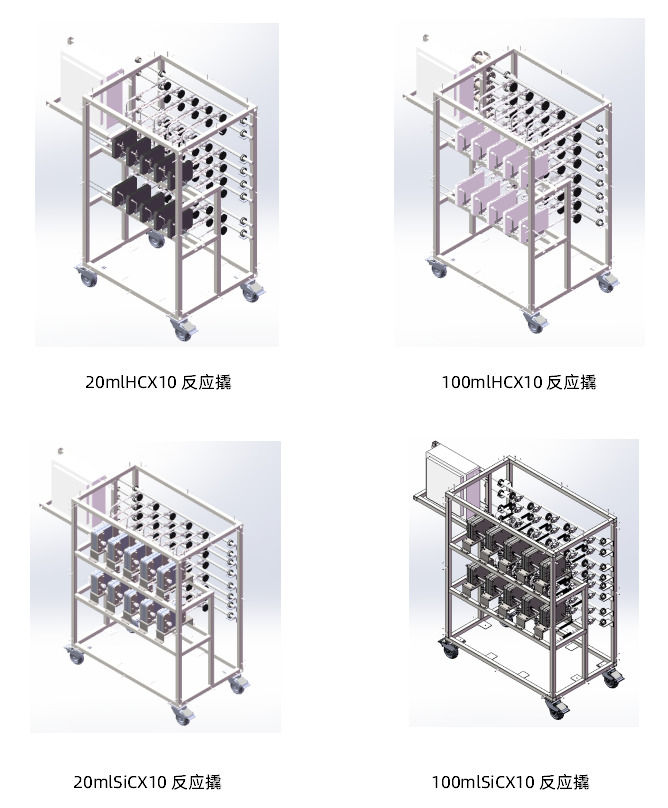

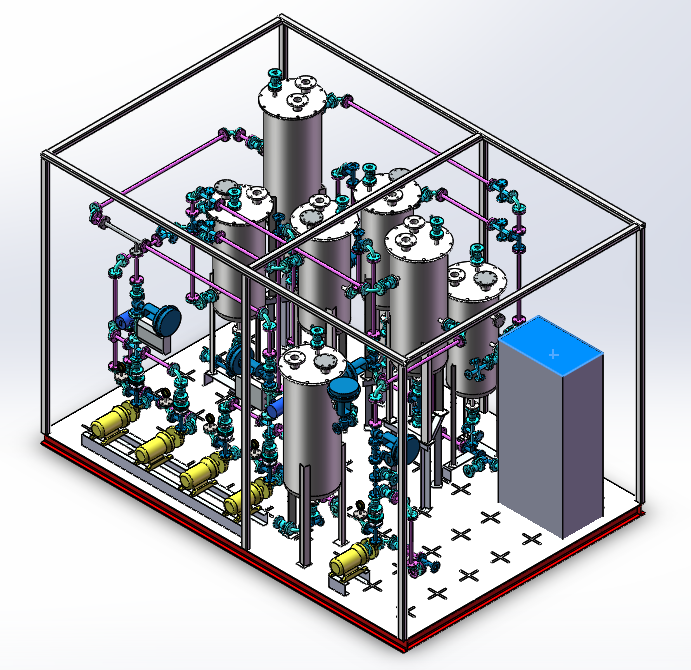

Continuous flow micro-reaction technology provides a new approach and method to solve the shortcomings and defects of traditional kettle synthesis. This technology can realize multi-step continuous flow automated synthesis and manufacturing from raw materials to API and even preparations through series or parallel reactors, without external intervention in the middle.